Petrofisa offers guardrail solutions made of Fiberglass Reinforced Polyester (FRP), ideal for industrial applications that require high mechanical strength, durability, and low maintenance. Our products are designed to meet strict safety standards, delivering reliable protection across a wide range of environments.

Advantages of Petrofisa’s FRP Guardrail

Corrosion Resistance: Resistant to chemical agents and aggressive environments such as chemical plants, petrochemical facilities, and marine structures.

Lightweight and Easy Installation: Much lighter than steel, FRP enables easier transport and assembly, reducing operational and labor costs.

Low Maintenance No need for painting or regular anti-corrosion treatments, leading to long-term savings.

Electrical Insulation: Excellent dielectric properties, enhancing safety in areas with potential electrical hazards.

Long Service Life: Maintains structural integrity even under harsh environmental conditions, ensuring extended durability.

> Industrial walkways and platforms

> Water and wastewater treatment plants

> Chemical handling facilities

> Offshore and marine environments

> Energy, sanitation, and infrastructure sectors

Petrofisa’s FRP guardrails are engineered in compliance with NR 12, NR 18, NBR 14718, and other applicable technical standards, ensuring safety, reliability, and regulatory adherence.

Our FRP guardrails are developed with a focus on safety, structural strength, and compliance. They are assembled using a combination of high-performance profiles and components tailored to meet diverse technical requirements.

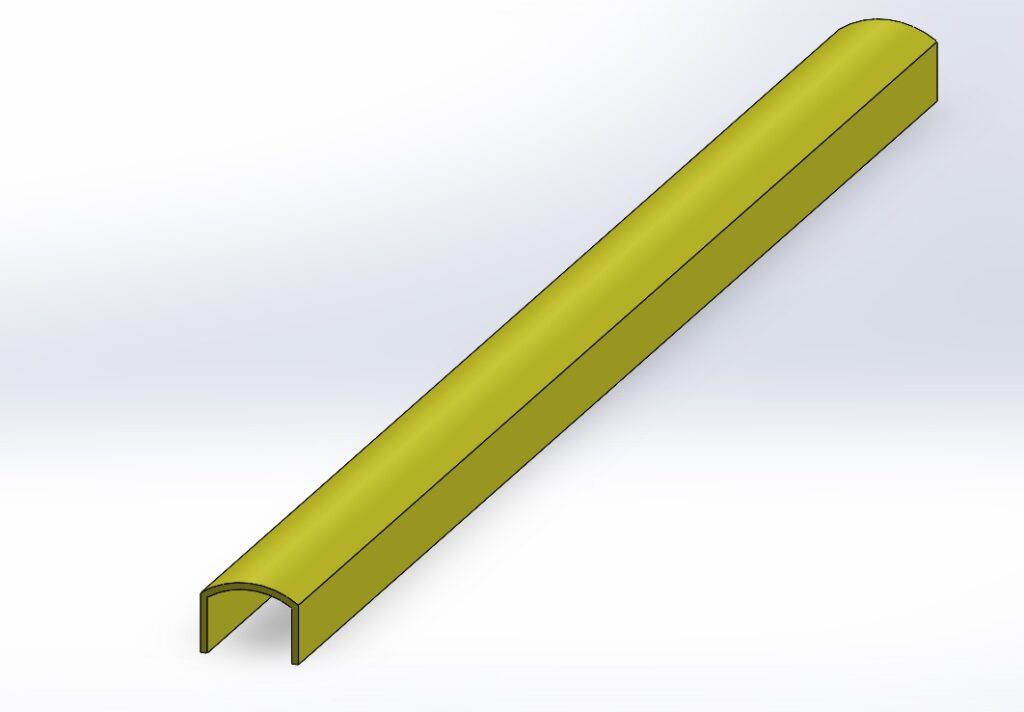

The upper section that provides user support. Manufactured in rounded or rectangular FRP profiles, it offers comfort, strength, and electrical insulation. Optional anti-slip surface available for wet or slippery conditions.

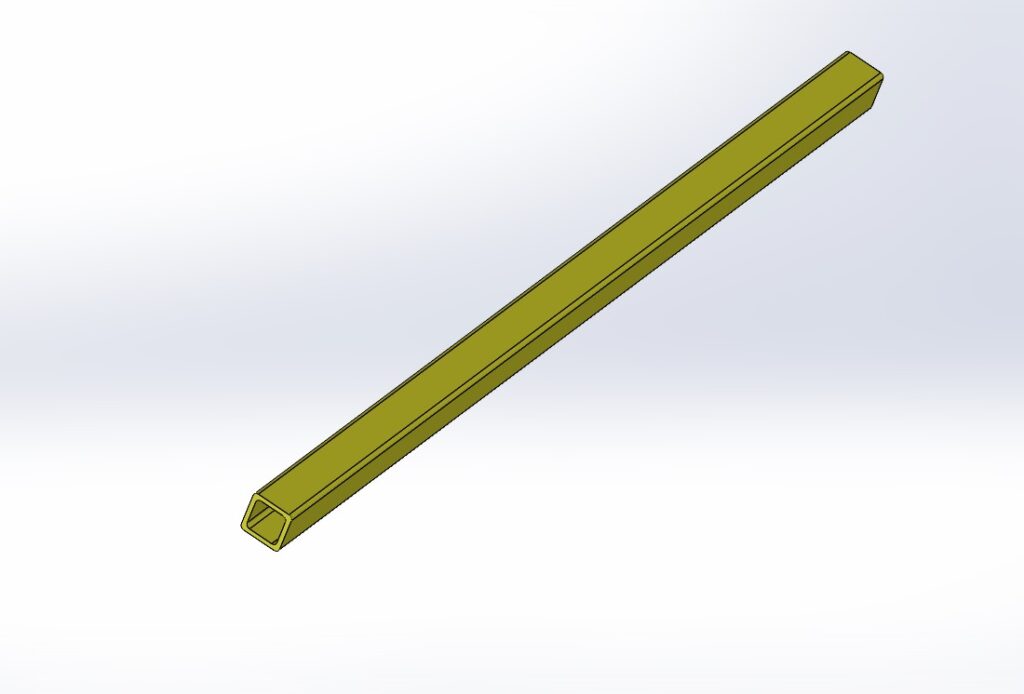

Used as vertical posts or secondary structural members. These square-section FRP profiles add rigidity, resist corrosion, and allow for easy integration with various guardrail configurations.

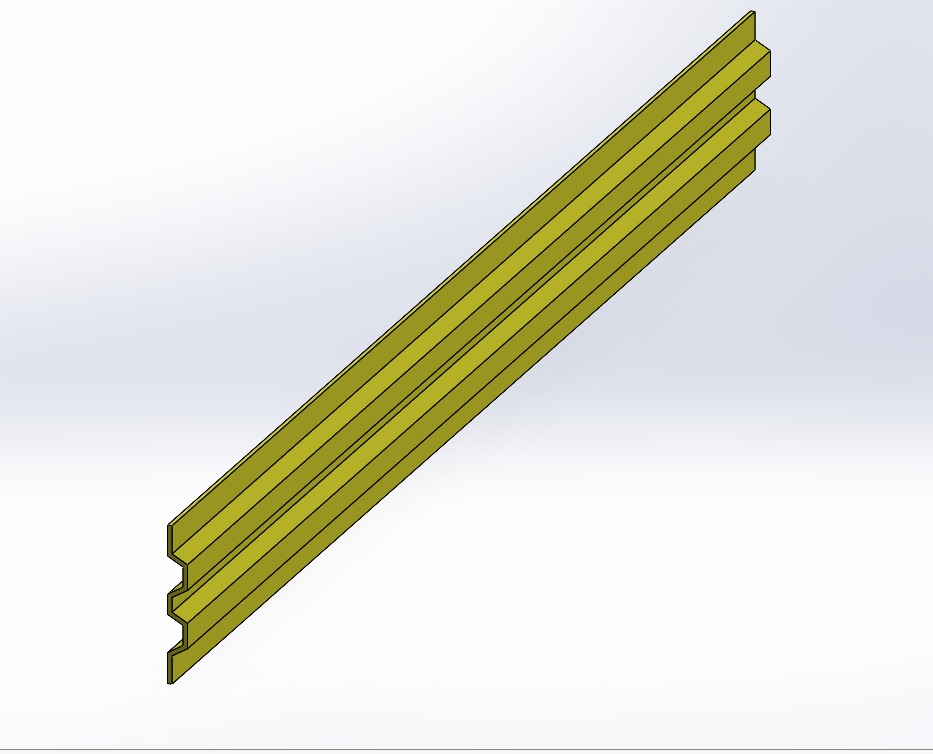

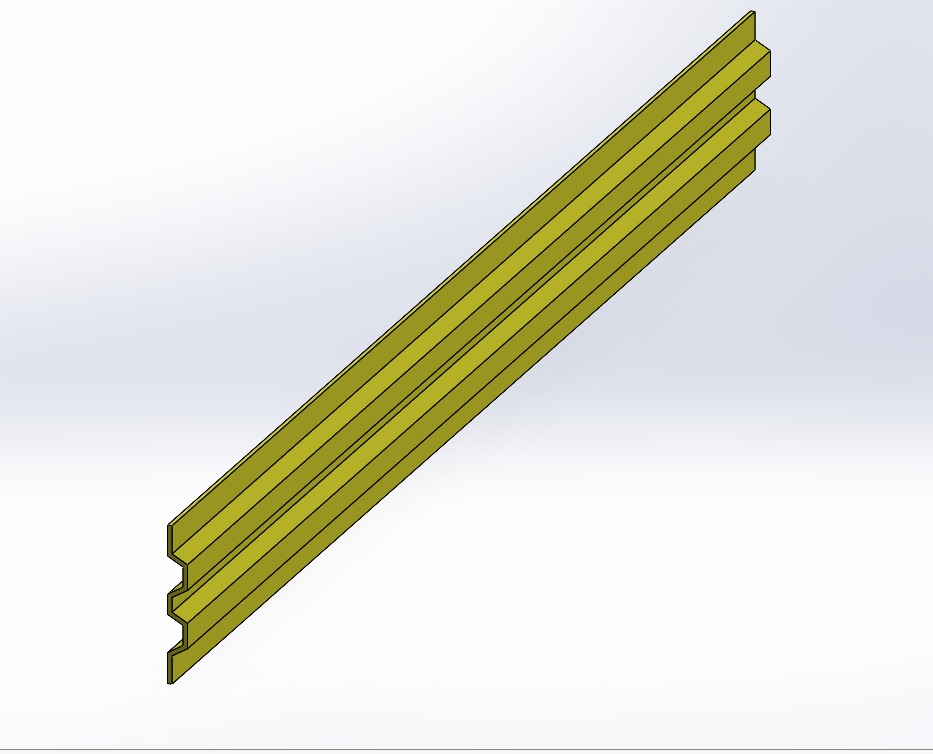

A horizontal cross member between posts, enhancing structural strength and fall protection. Multi-level configuration complies with NR-12 and is suited for elevated platforms and technical areas.

A simplified version of the Greek Bar, used in areas with lower fall risk or where visibility and ventilation are priorities. It still ensures safety and preserves the technical integrity of the system.